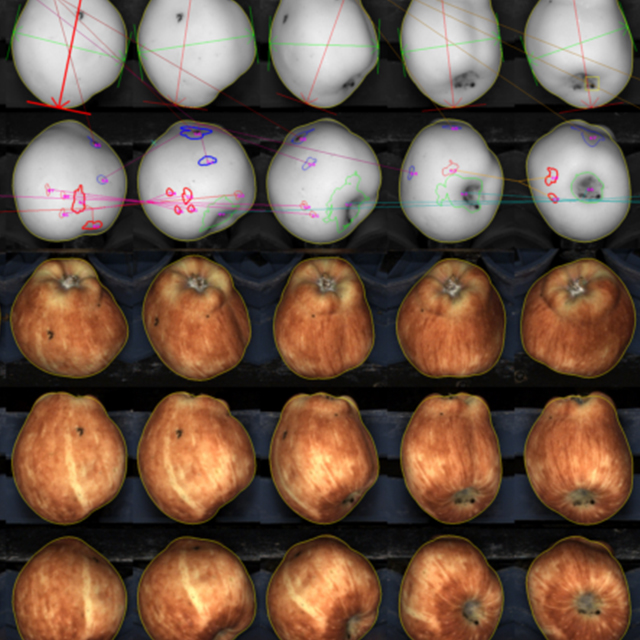

Detect challenging defects

Time savings and simplicity

Enhance operators skill

Deep Learning True-AI

Detect challenging defects

Time savings and simplicity

Enhance operators skill

35

+

Years of expertise in grading and sorting technology

3500

+

Ellips grading systems in use worldwide

19

Types of fruits and vegetables covered

350

+

Elisam and Elifab grading machines operating globally

With so many different ways for defects to appear across every piece of fruit and vegetable, it’s only through True-AI that we can accurately model all these combinations. Advanced grading software that gives your company the edge.

Self-learning AI

True-AI is an advanced self-learning system that constantly gets smarter with new data measurements taken from different seasons and conditions by operators worldwide. Such collective strength advances the software for the benefit of all.

Simplified grading

With True-AI all the grading parameter tasks are automated, saving your operator a lot of time. Everything is ready to go straight out of the box so the algorithms can be applied without any need for modifications. Added to this, all the grading settings are very user-friendly, so when adjustments are needed, it’s all incredibly efficient.

Highly efficient

True-AI works with your operator to maximise reliability and efficiency. By combining True-AI’s advanced software with their market understanding and product knowledge, you have a team that accurately grade produce at amazing speed.