Maximize your harvest value with AI onion grading

Ready to grow your business but struggle with quality, costs, and labor? Discover the video to explore all benefits of AI-driven onion grading.

Discover AI videoOnion grading machine

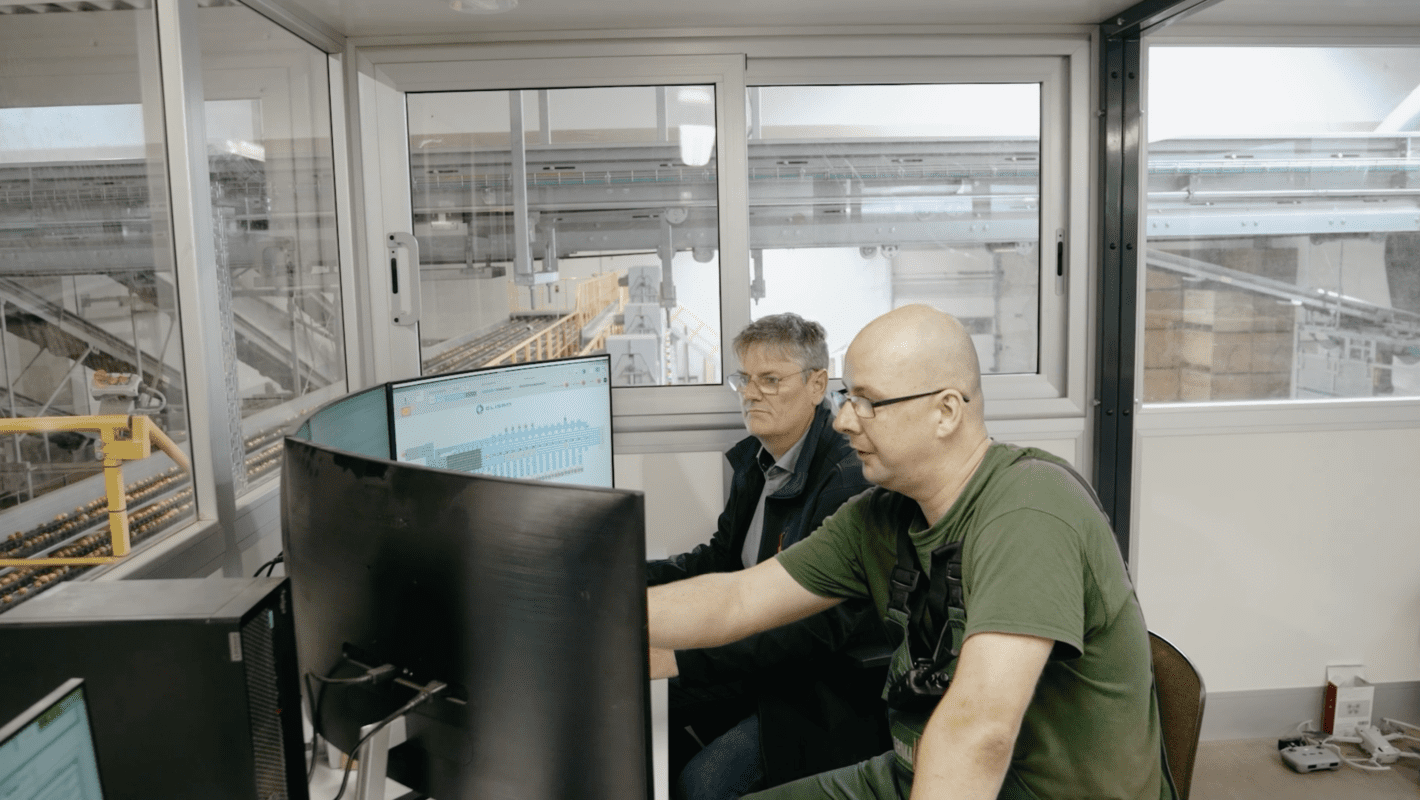

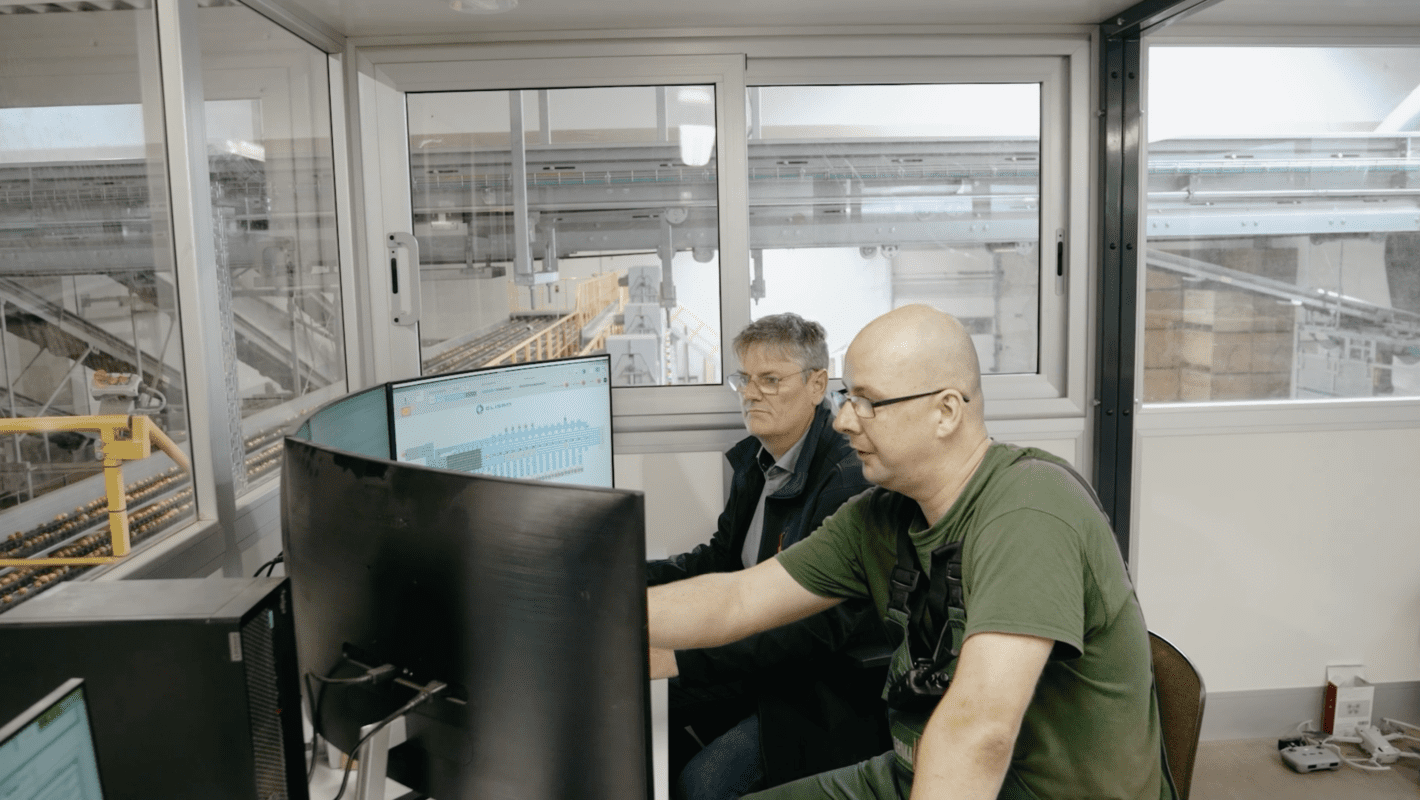

Elisam grading machine

powered by Ellips technology

Do you have the ambition to increase the capacity of your business? Are you facing challenges such as labor issues and inconsistent quality? With our leading onion grading machine you have the full control to grow as a preferred supplier.

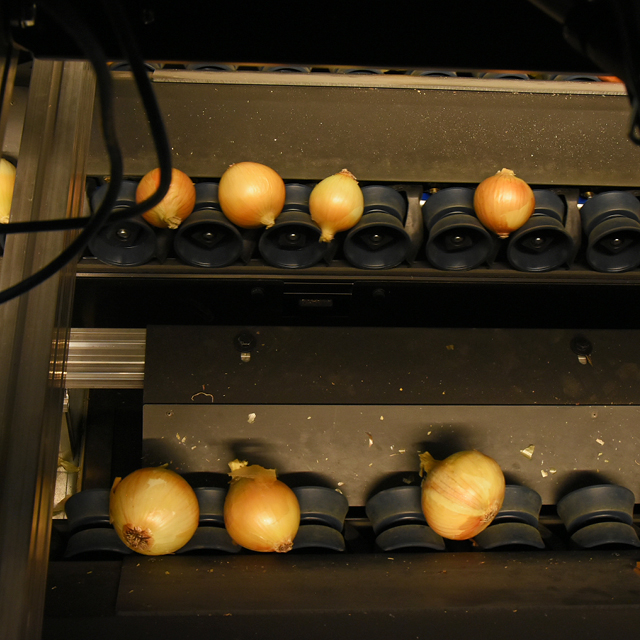

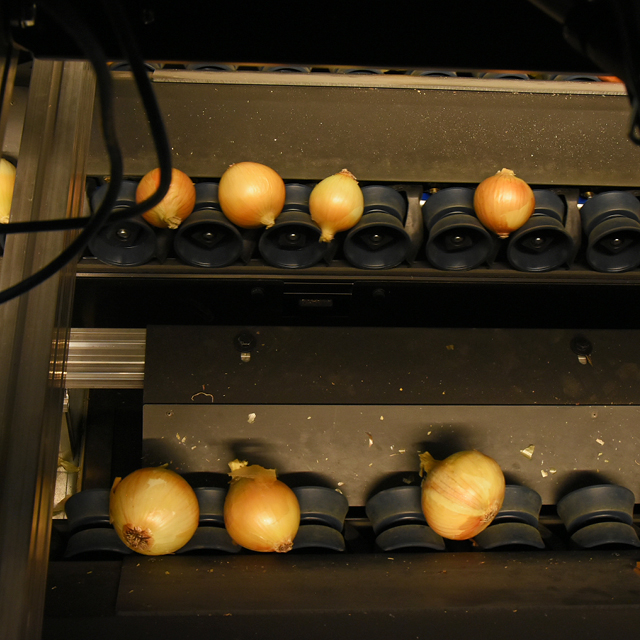

Every onion counts, every single minute of grading is important – it’s why the Elisam GranTorino onion grading machine is build for speed and exceptional capacity. Such huge throughput will transform your business productivity, profitability and reduce dependance on labor. Make every single onion from your harvest count, with minimal waste.

Explore how to expand your grading capacity

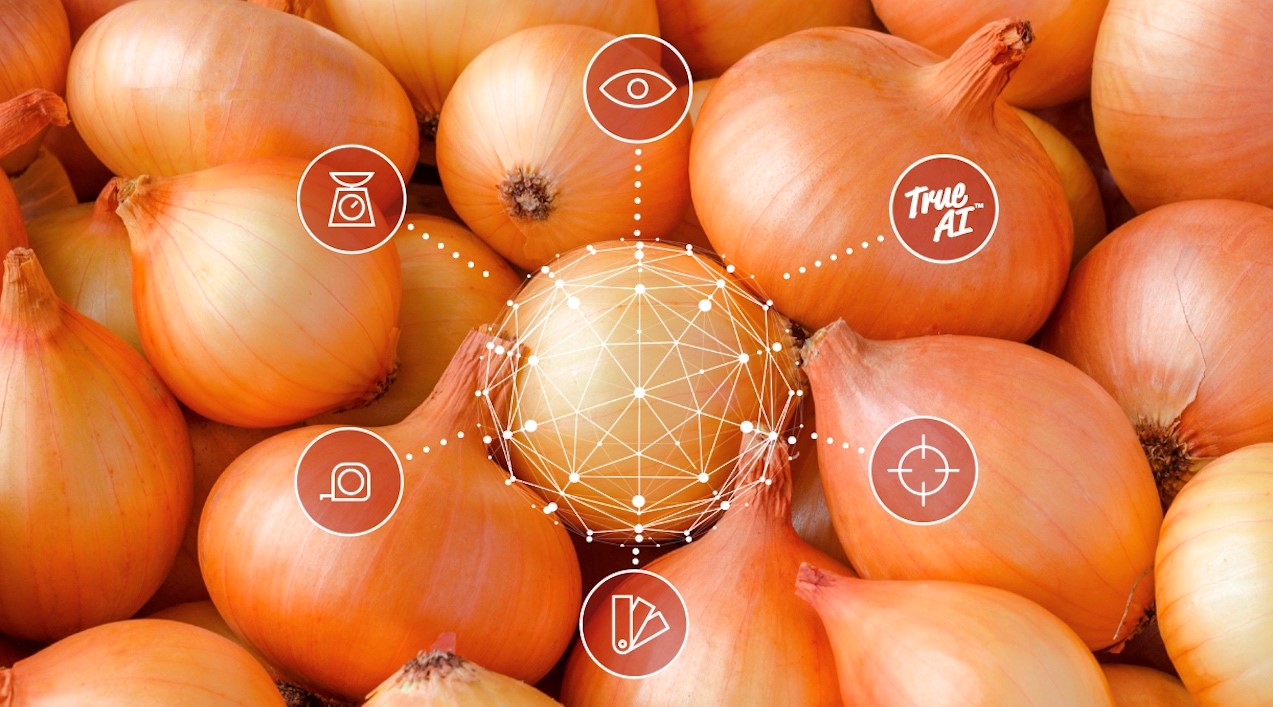

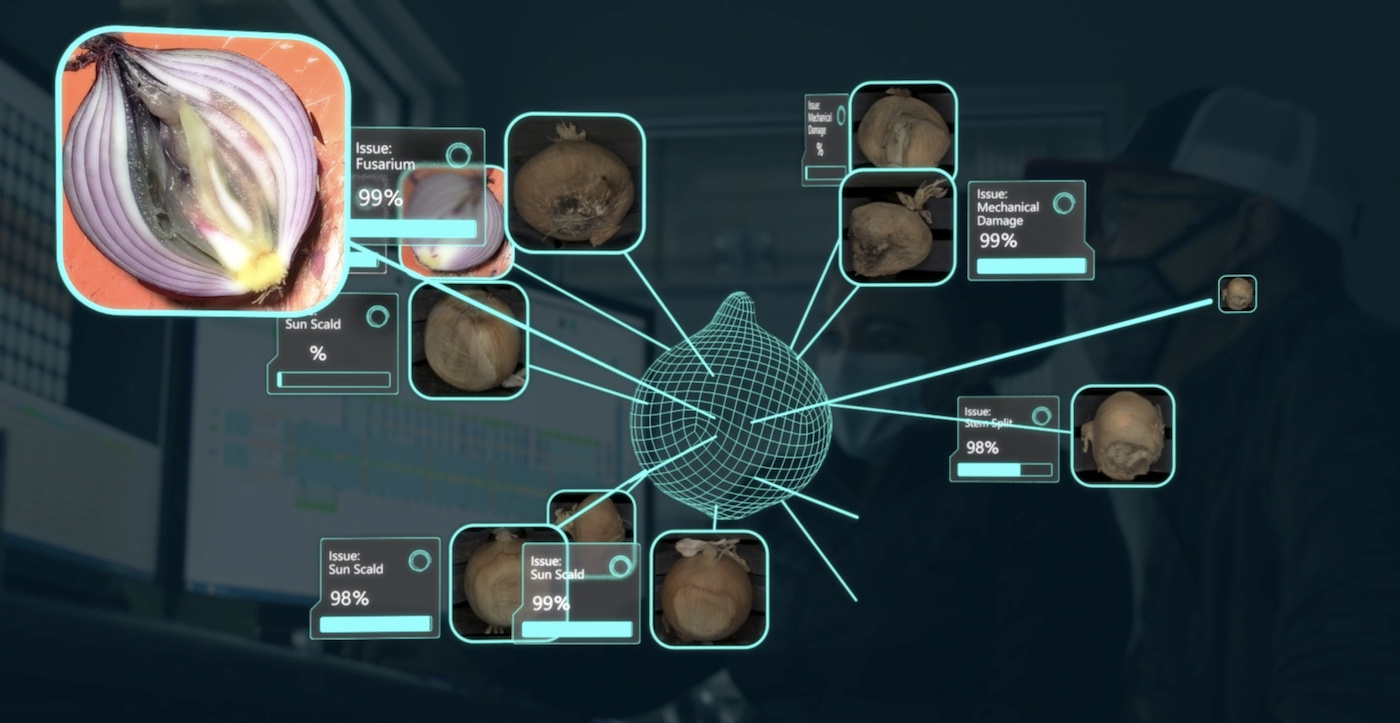

By consistently achieving your client’s quality requirements every season, it takes your reputation to the next level. And so GranTorino analyzes each onion inside and out, detecting size, weight, color, rot, mold, sprouting, fusarium, root tear, balding, mechanical damage and more. With every onion graded correctly, you’ll maximize the return on each harvest while delivering exactly what your customer needs.

Discover how to achieve consistent quality

When it comes to growing onions, you’re the expert. And when it comes to growing revenue, we know how to help. With the combination of our world-class grading software and the GranTorino grading machine you’ll get the most value from your onions by maximizing yields and reducing food waste. It’s highly flexible and lets you to meet any market demands or export criteria – helping you strengthen your position as a preferred supplier and achieve a faster return on investment.

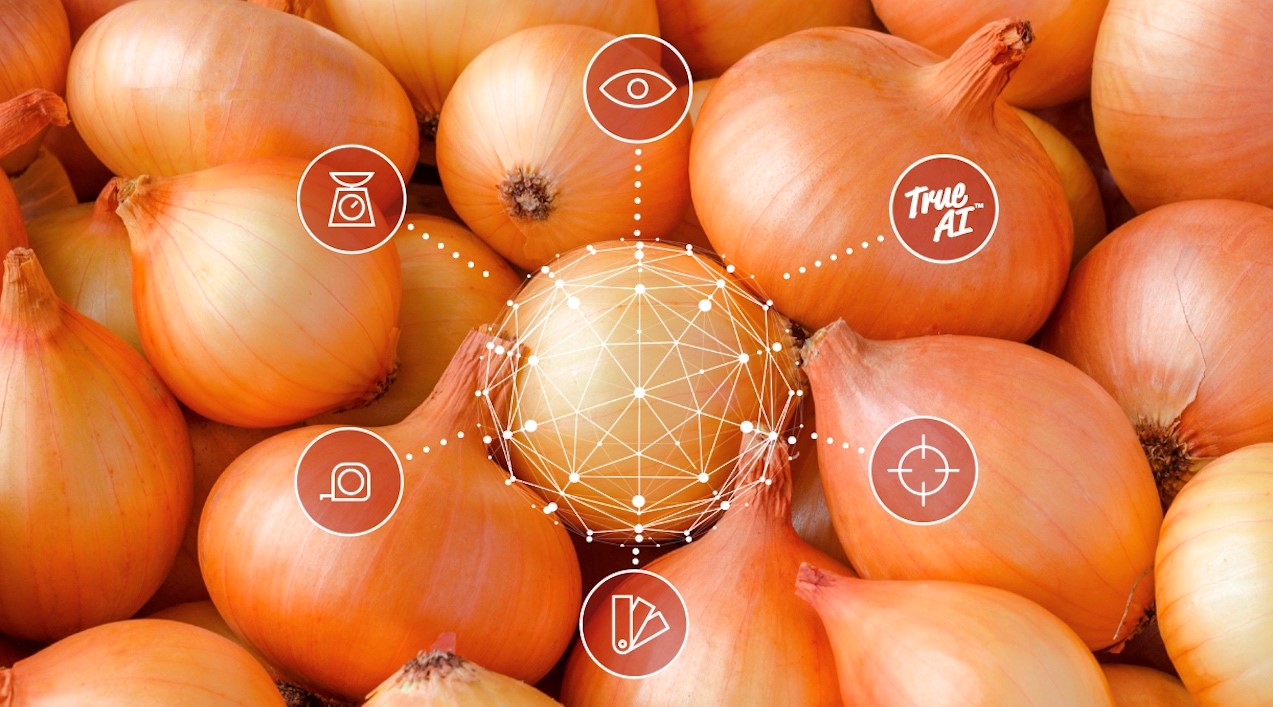

Ellips developed a new technology called True-AI. You can now deliver near-perfect grading accuracy through superior detection of the most challenging defects and onion characteristics such as fusarium, misshapen and root tear. The new software has been trained using large amounts of data combined with the expertise of quality control personnel.

Discover the powerful benefits of True-AI

The robust and reliable Elisam GranTorino is an industry-leading onion grading machine. Its unique mechanical design delivers gentle, yet fast and accurate handling of any type of onion. Everything your business needs to accelerate its success.

Discover the GranTorino

Working directly with hundreds of packhouses around the globe, we’ve fully integrated our machines into each individual facility. Together with our partners, we’ll do the same for you ensuring your entire packhouse is optimized and seamlessly connected across multi-head weighers, bin tippers, washing and waxing machines, drying tunnels, palletizers, packing tables and automated packaging.

As we offer a complete solution, our service doesn’t stop once the onions are graded, we can also offer customized packaging solutions. Our technology is designed to reduce packing and labor costs, whilst making your packhouse more efficient. As it’s an automated system, it will distribute the onions into boxes, bags, bins, totes or tanks, eliminating the need for human labor.

Ready to grow your business but struggle with quality, costs, and labor? Discover the video to explore all benefits of AI-driven onion grading.

Discover AI video

Discover how Target AG achieves consistent onion quality, faster processing, and lower costs with Ellips True-AI. Explore powerful defect detection.

Discover Customer Story

Do you have a reliable labor force to be fully operational? Are you achieving maximum capacity to exploit full market potential? Discover your solution.

Explore article

Groka has set ambitious goals to double its capacity within a span of 5 years. However, achieving these aspirations comes with its fair share of challenges.

Discover Customer Story

Do you suffer from quality inconsistency due to extreme growing conditions? Are you struggling to sort out challenging defects? Discover your solution.

Explore article

Increased profitability, significant cost savings and minimal labor required. This is why Artificial Intelligence is changing the game for onion growers and packers.

Explore AI article

Outstanding test results demonstrated huge market potential. Onion industry leaders are convinced of TrueAI’s return on investment and operational efficiency.

Explore article