- Optimize throughput

- Less labor

- Consistent quality

Cherry tomato grading machine

Next-gen cherry tomato grading machine

Elifab grading machine

powered by Ellips technology

Cherry tomato grading machine:

This is how you unlock the full potential of every harvest.

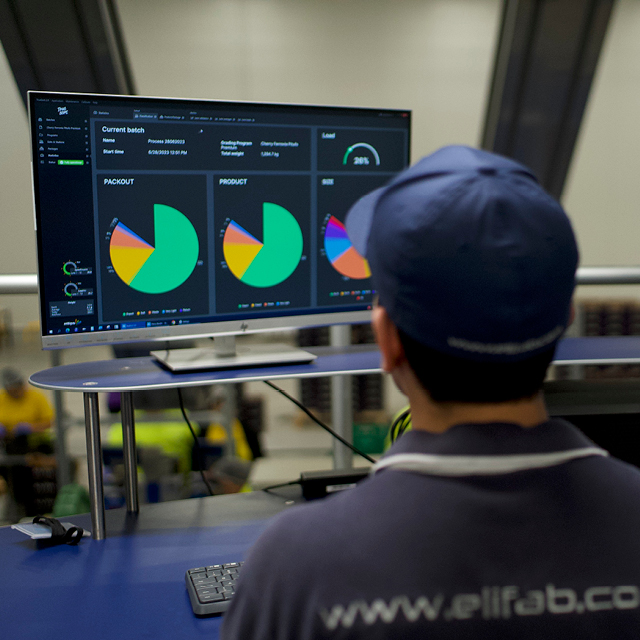

Do you want to increase your grading capacity while tackling challenges like labor shortages and inconsistent quality? This AI-powered grading machine delivers the most gentle treatment of every cherry—while achieving the highest throughput per sorting lane. You stay in full control, protecting your quality standards and boosting your profits, season after season.

Maximize throughput with less labor

Give your packhouse the ability to accurately sort millions of individual cherry tomatoes at exceptional speed without damaging the fruit. As everything is automated with our Tomato Class grading machine, you’ll maximize your throughput with consistent quality and reduce the need for workers.

Consistent, market-leading quality that sells itself

Extract the most value from every batch and maintain your reputation for quality with superior accuracy. High-tech cameras capture 30 images for every single cherry tomato, resulting in near-perfect size, color separation, brix detection (sweetness) and highly accurate sorting of defects such as softness, stem, rot, splits, cell breakdown, cuts and stink bug marks.

Compact design that saves space—and money

Thanks to our compact machine footprint—almost half the size of many competitors—you’ll also minimize your initial investment in packhouse space and construction. Plus, with a smaller system volume, you’ll cut daily refrigeration costs, saving on both energy and operational expenses.

Extract max value from every cherry tomato

When it comes to growing cherry tomatoes, you’re the expert. And when it comes to growing revenue, we know how to help. With the combination of our world-class grading software and the Tomato Class grading machine you’ll get the most value from every single cherry tomato, by maximizing yields and reducing food waste. Plus you’ll be able to meet specific customer demands such as longer shelf-life cherry tomato or larger cherry tomatoes, strengthening your position as a preferred supplier and achieve a faster return on your investment.

Advanced cherry tomato grading

Elifab Tomato Class cherry tomato sorting machine

Trusted by world’s best growers and packers, Elifab Tomato Class grading machine is an industry-leading solution. Not only are you guaranteed the lowest total cost of ownership, but you’ll be able to stay at maximum speed to meet all delivery and quality needs.

- Consistent quality at high speed Cherry tomato season is short, packhouse space is often limited, and you want to process and pack your harvest to get it to your customers as quickly as possible. It’s why growers and packers trust the Elifab Tomato Class sorting machine that combines incredible speed and accuracy, with delicate handling and huge capacity.

- Delicate handling, even at top speed.Fast processing shouldn’t come at the expense of fruit. It’s why Elifab uses our world-first, specially designed silicon curtains that reduce speed whilst keeping the fruit separated. Together with the lowest transfer height throughout the whole process, we have achieved the most delicate handling with little or no impact on your cherry tomatoes.

- Cleverly designed to fit any packhouse World-class quality doesn’t have to mean giant machinery. By collaborating with customers in packhouses of all shapes and sizes, we designed Elifab to have the smallest footprint in the market. Added to this, its compact cherry tomato sorting machinery can be installed quickly and is very easy to maintain and clean – meeting all strict food safety requirements.

Discover the Tomato Class

Cherry tomato grading and packing with the finest results.

It’s all fully integrated so your entire packhouse works as one

Working directly with hundreds of packhouses around the globe, we’ve fully integrated our cherry tomato grading machines into each individual facility. Together with our partners, we’ll do the same for you ensuring your entire packhouse is optimized and seamlessly connected across multi-head weighers, bin tippers, washing and waxing machines, drying tunnels, palletizers and cherry tomato packing machine (packing tables and automated packaging).

Cherry tomato packing machine

With MatExakta cherry tomato packing machine, everything is taken care of with minimal human intervention. It’s an automatic weighing and packaging solution, that allows you to easily switch between different packaging materials such as cartons, plastic, paper pulp and forms like punnets, shakers, buckets, and clamshells. Whatever’s used, everything happens automatically and precisely, down to the lids being placed on the trays and labelling with the correct label.