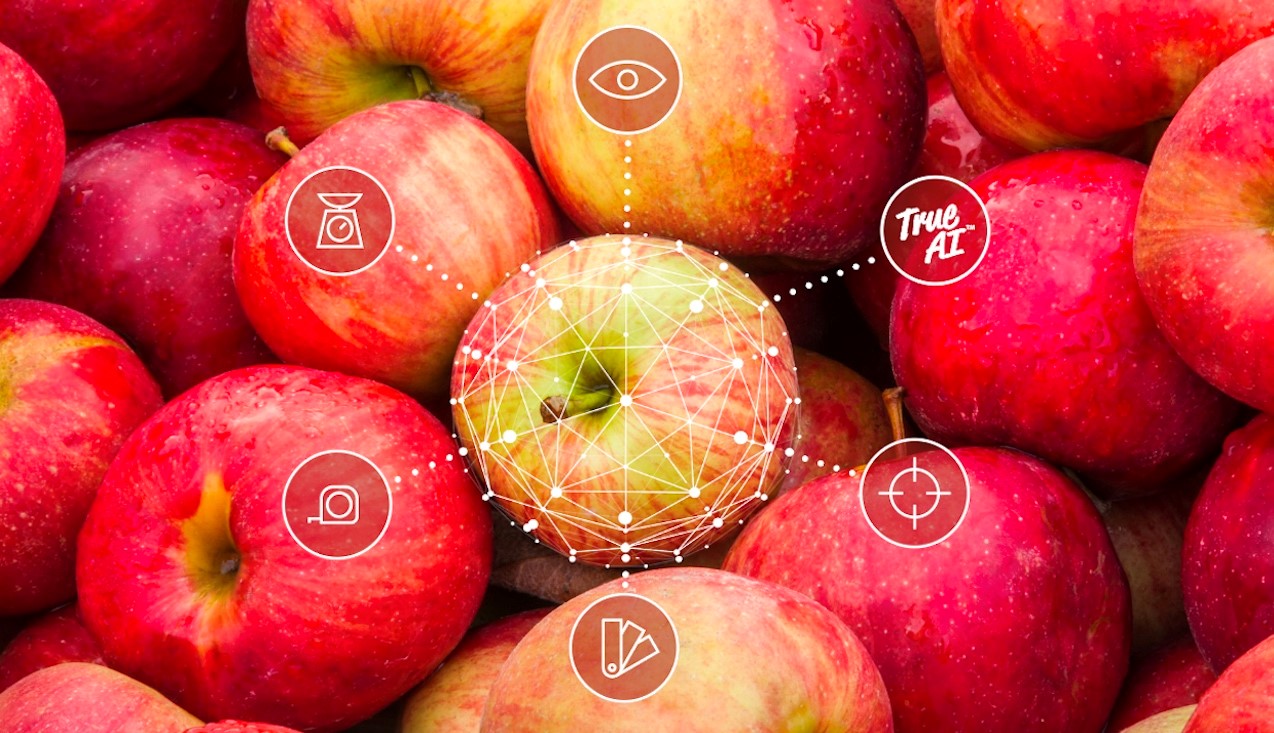

This is why Starr Ranch Growers chose Ellips-Elisam after 5 years of tremendous studies.

Starr Ranch has implemented Ellips’ apple grading technology. The choice is based on the proven color, defect and internal quality grading.

Discover Customer Story